P

r

o

d

u

c

t

s

TSMOST, a specialized automotive parts specialist with differentiated impact and competitiveness.

Electronics Division

Product Description

Definition & Role

Also known as Smart Battery Sensor, it determines the SOC, SOH, and SOF of the battery to increase vehicle convenience, improve fuel efficiency, reduce fuel consumption, and reduce emissions. It can operate as follows depending on the OEM application.

- AMS(Alternator Managment System) : Generator Control(Optimal control of battery charging/discharging and alternator)

- ISG(Idle Stop Go) : Turns off the engine when the vehicle is stationary and turns it on when starting.

- Provides voice or visual warnings to prevent discharging below the minimum battery capacity required for SOC display and engine restart.

※ Terminology Definitions

- SOC(State Of Charge) : Refers to the battery's charge status, defined as 100% when fully charged.

- SOH(State Of Health) : Refers to the battery's health status, assessing its condition to extend its lifespan.

- SOF(State Of Function) : Refers to the performance status of the battery, evaluating its capability to ensure reliable cranking.

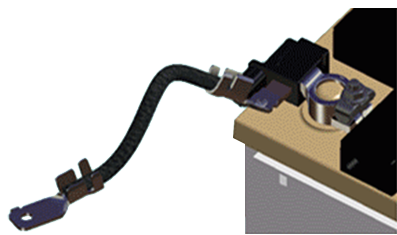

Product composition & mounting

- Composition

-

- Battery Minus Clamp Assembly

- Sensor Housing & Connector

- Shunt Resistor

- Cable Assembly

- Operating Principle

-

After measuring the battery's V, I, and T, the SOC, SOH, and SOF are determined.

- V(Voltage) Measurement : Measures the voltage of the battery.

- I(Current) Measurement : Measures the charging and discharging current of the battery using the voltage across the shunt resistor and the shunt's inherent resistance value.

- T(Temperature) Measurement :Determines the temperature around the battery to indirectly extract the internal temperature of the battery.

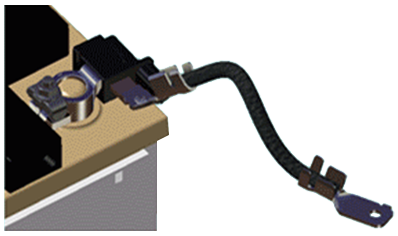

Types & Mounting

- 1st Generation

- Mounting

- 2st Generation

- Mounting

Product Application

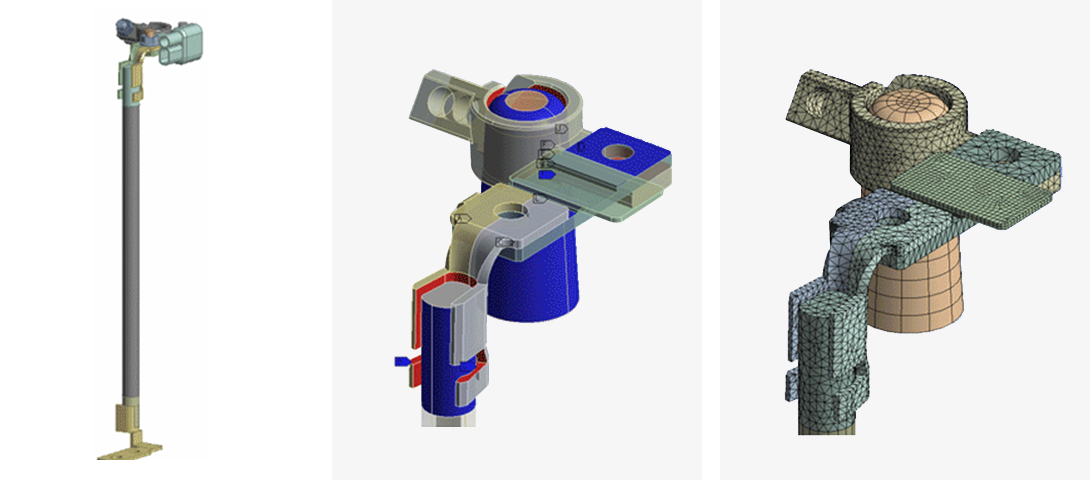

ASSY Vibration and Component Structural Analysis(CAE)

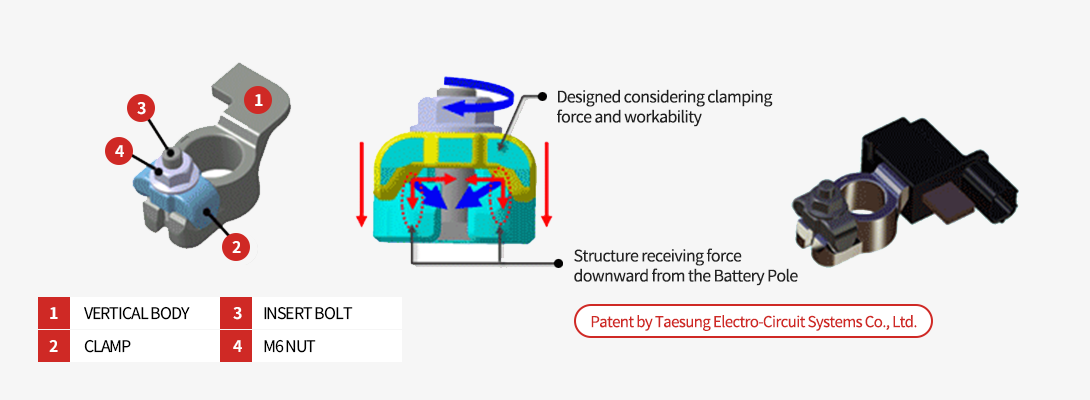

Vertical Type POST TERMINAL

Advantages

- 01Uniform force is transmitted when clamping the Battery Pole

- 02The presence of a CLAMP prevents excessive force transmission

- 03Maintains high and uniform clamping force during repeated clamping

- 04Low risk of damage and easy to work with

- 05No damage to the Battery Pole

Comparison with

other companies

Please move the screen left and right.

Please move the screen left and right.

| Category | TSMOST | Company A | Company B |

|---|---|---|---|

| Structure | Upward Type | 20.3 Nm | |

| Surface Pressure Measurement |

|

|

|

| Average Rotational Holding Force |

20.3 Nm | 7.5 Nm | 14.3 Nm |

| Results |

|

|

|

- urface Pressure Measurement Experiment Conditions : Used MS medium pressure sensitive paper (measured after fastening with 8 Nm torque)

- Rotational Holding Force Experiment Conditions : Measured rotational holding force after fastening with 4 Nm torque on the Battery Pole